Among the many possible uses of Microsoft Excel is the building of a CMMS (Computerized Maintenance Management System). Although Excel was not designed specifically for this purpose, many companies have long used it, or still use it, to manage their maintenance, rather than using purpose-built, dedicated software.

Therefore, why use a CMMS application if Excel can perform the same function? In practice, maintenance management becomes much easier and more efficient when using a dedicated and innovative solution rather than a mere spreadsheet application, which, despite its apparent advantages, has many limitations.

Creating your own CMMS from Excel

Excel, the famous spreadsheet application, is used by many companies as a maintenance management tool.

Why use Excel to manage your maintenance?

Those who are quite familiar with Excel know that it is possible to create their own CMMS with it. With time and inventiveness, Excel can become a useful tool for planning maintenance visits, managing equipment or keeping track of inventory.

Indeed, Microsoft Excel has several advantages:

- It is free of charge (assuming that it is already installed on the company’s computers, as is often the case);

- It does not require highly specialized training;

- It offers great flexibility in that many different types of data can be saved in the spreadsheet;

- It is easily customizable;

- It allows for easy exchange of information between employees.

For all these reasons, shortly after appearing on the market, Excel quickly replaced paper documents in the industry, and it remains today a solution used by many companies, particularly SMEs, who see it as the most affordable solution.

Limitations of Excel for CMMSs

Nevertheless, Excel has serious limitations for those who want to optimize their maintenance management:

- It does not offer any alerting or notification feature;

- It can hardly be used by several people simultaneously;

- It creates a degree of uncertainty about the reliability of available data, because of inherent risks of errors or potential problems with document updating;

- It leads to excessive centralization of information, knowing how good maintenance management is based on collaborative data sharing by numerous parties;

- It is limited in terms of big data analysis and cross-referencing capabilities.

Generally speaking, Excel hinders information sharing, collaborative practices and teamwork, which are powerful drivers of maintenance team involvement. It also lacks features specifically designed to facilitate maintenance management and workspace management – a missed opportunity for employees or office workers who would benefit from an application environment that would make their workaday life more pleasant.

Furthermore, Excel spreadsheets are not able to properly link a floor plan to the offices on it, the equipment in each office and the people occupying each office. In practice, if changes are made in any office, a CMMS under Excel will have to be updated manually – a particularly time-consuming and costly process in situations where changes occur frequently.

This is where adopting a dedicated CMMS application to optimize maintenance tasks becomes more sensible than continuing to use Excel.

Why choose a dedicated CMMS application rather than Excel to manage your maintenance?

There are many good reasons to choose a dedicated professional software application rather than Excel to manage your maintenance tasks.

What is a CMMS application?

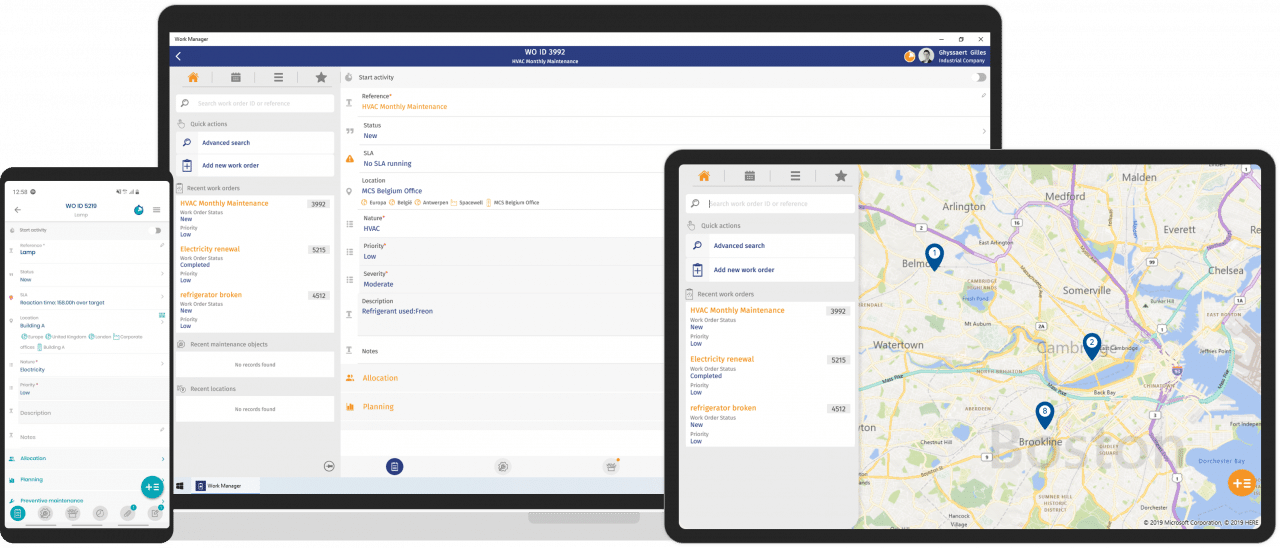

Unlike Excel, CMMS software applications are specifically designed to facilitate and optimize maintenance management by a clever use of digital tools. This type of solution generally has modules or functions allowing you to:

- List every piece of equipment to be maintained, with their technical characteristics, including copies of their documentation;

- Schedule and keep track of all service visit requests;

- Fill out and edit maintenance reports;

- Check the service history of each equipment;

- Manage data access and editing rights for each type of user;

- Manage spare parts inventories;

- Gather statistics on maintenance activities.

Why use a CMMS application rather than Excel to manage your maintenance?

A CMMS application makes it easier not only to manage maintenance, but more importantly to optimize maintenance, so as to improve your company’s productivity.

Features designed to optimize maintenance

As mentioned earlier, a dedicated CMMS solution gives you access to advanced maintenance management features. These features allow you to streamline every step of the maintenance process, from service visits scheduling to spare parts inventory management, as well as work shift scheduling and equipment operation analyses. Streamlining is the key to optimizing maintenance and enhancing company productivity.

Moreover, a professional CMMS application can generally be customized to the specific needs and distinctive features of the company. Thus, you can obtain the same level of flexibility and customization as with Excel.

Useful aid

By adopting a CMMS application, the company acquires not only a powerful maintenance management tool, but also associated services, such as a customer support service. With such support, maintenance managers can feel confident that they will rapidly be able to make the most of their software tool, as opposed to having to spend time researching by themselves solutions to specific problems that will likely crop up at some point or another in the future.

Moderate cost

The fact that Excel is almost free of charge is often considered to be one of its main advantages in the matter. Yet, although a CMMS application inevitably adds a cost, it is important to take a step back and look at the big picture when considering the cost effectiveness of such a solution. Firstly, the cost can be paid as a subscription: rather than having to purchase a perpetual license and pay the full price, companies can gain access to the application for a monthly or yearly license subscription fee, thereby avoiding the need to make a significant and uncertain financial investment.

Moreover, and perhaps more importantly, the time saved and the productivity gains achieved by using a CMMS application instead of Excel will more than compensate the cost over a relatively short period of time.

Innovation at your fingertips

Finally, any company that uses a dedicated CMMS application will be able to take advantage of the latest technologies to improve its productivity. Innovations such as the Internet of Things (IoT), BIM (building information modeling) and smart buildings, increasingly used in maintenance nowadays, can be gradually integrated into your company’s operations and the work of your engineers. By adopting a CMMS application, your company will be able to adapt to present and future technology evolutions as well as maintain and improve its competitiveness.

Selecting the right CMMS application

Adopting a professional CMMS solution is always a step forward compared to using a spreadsheet to manage a company’s maintenance operations. However, it is important to select the right software to fully benefit from such an implementation.

In particular, it is important to choose a mobile solution that is available on any connected device and is also user-friendly. Indeed, the application’s user-friendliness is critical for the changeover to be well accepted by those on the job and for them to utilize the application to its full potential – a requirement which, if not met, could render the investment counter-productive.

Although Excel used to be, arguably, an adequate solution to facilitate and improve maintenance management, its comparative advantages have gradually faded as professional CMMS applications have improved.

Today, dedicated CMMS applications offer many valuable advantages that make them a better choice, allowing companies to achieve significant productivity gains while facilitating the work of their maintenance teams. These modern tools are undoubtedly spearheading the future of maintenance.

Frequently asked questions

CMMS software usually foresees the transfer of statistics from the old tool (here: Excel). Should you have any doubts, do not hesitate to ask for a free trial on the Spacewell website to obtain more information.

A CMMS software provides a more comprehensive maintenance management solution than Excel. For example, Excel is not the optimal alternative when you work with several people or when you need reliable data in real time.